Anyone want to make some extra cash? I want to learn how to weld

#16

I can teach you pretty much all you need to know about MIG welding for automotive purposes and general sculptures if you want.

I'm in Saratoga. PM me if you want to come by and spend an hour or two makin' some beads.

I was in the same boat as you with aluminum, but I found it takes a whole other set up and I really don't weld AL as much as I thought I would.

But I've done enough work on my car alone that I've paid for my $600 welder over and over again. There's also a really cool feeling of accomplishment when you take raw materials (tubing, plate metal) and create a functional, structural automotive design and weld it up and to the car and it comes out just right and just how you imagined it.

From this:

(bashed up my rad support and subframe brace)

To this:

I had some other side/lower pics, but lost the memory card....that lowest bar replaces the subframe and the skid plate mounts up to it in the stock location (with weldnuts).

all that was done with less than $200 in materials and my own time (and 1 hours of my buddy's time with a tubing bender).

It was also about 32lbs of weight reduction off the front of the car (front bumper is heavy!!!)

plus, joining two pieces of metal by controlling small pools of liquid hot magma with high levels of electrical current is just f'ing studly.

PS, I made those jack stands too....love'm

I'm in Saratoga. PM me if you want to come by and spend an hour or two makin' some beads.

I was in the same boat as you with aluminum, but I found it takes a whole other set up and I really don't weld AL as much as I thought I would.

But I've done enough work on my car alone that I've paid for my $600 welder over and over again. There's also a really cool feeling of accomplishment when you take raw materials (tubing, plate metal) and create a functional, structural automotive design and weld it up and to the car and it comes out just right and just how you imagined it.

From this:

(bashed up my rad support and subframe brace)

To this:

I had some other side/lower pics, but lost the memory card....that lowest bar replaces the subframe and the skid plate mounts up to it in the stock location (with weldnuts).

all that was done with less than $200 in materials and my own time (and 1 hours of my buddy's time with a tubing bender).

It was also about 32lbs of weight reduction off the front of the car (front bumper is heavy!!!)

plus, joining two pieces of metal by controlling small pools of liquid hot magma with high levels of electrical current is just f'ing studly.

PS, I made those jack stands too....love'm

#17

Registered User

iTrader: (3)

Once you learn the basics, all the skills are in practice.

I have done over head mig, thick to thin mig, tig, vertical tig, copings for tubing. I'd start with mig as it's the easiest, and tig practice doing fusion welds with tig so you learn how to control a steady bead before you actually weld a piece together.

I have done over head mig, thick to thin mig, tig, vertical tig, copings for tubing. I'd start with mig as it's the easiest, and tig practice doing fusion welds with tig so you learn how to control a steady bead before you actually weld a piece together.

#18

Registered User

iTrader: (2)

Join Date: Sep 2007

Location: Discovery Bay, CA

Posts: 1,569

Car Info: Evo X GSR, F250 Powerstroke Diesel

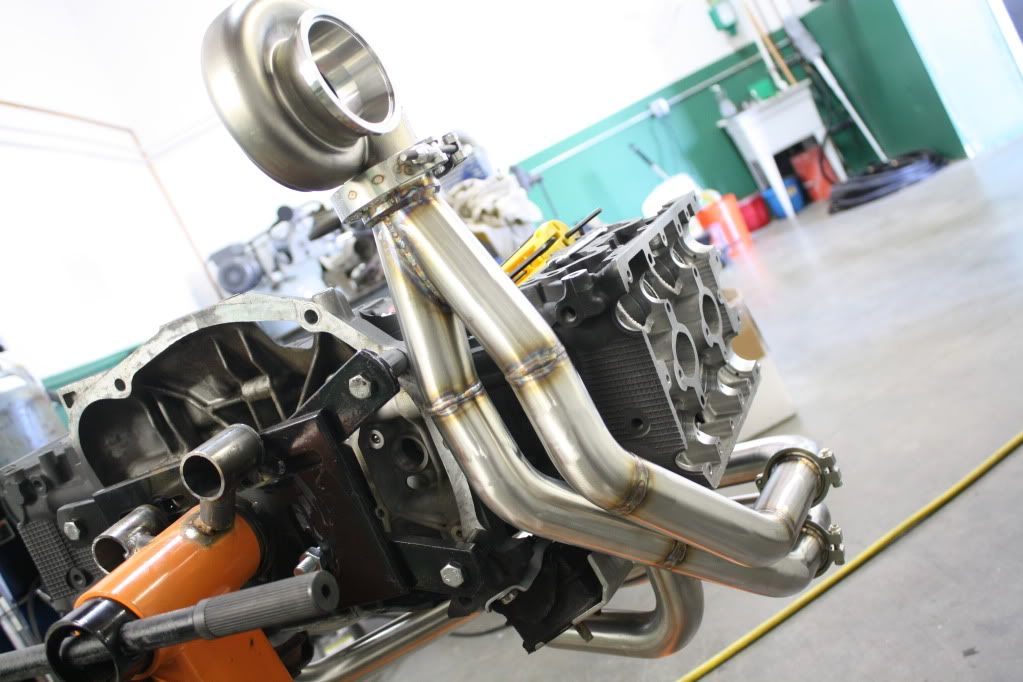

Hey Bruce, I got a garage full of metal fab equiptment if you are really interested in learning. I got a nice 200 amp AC/DC TIG and stick, and all kinds of metal fab tools. I am a AWS and ASME section IX certified pipe welder, and do allot of side work as well. Here is a evo 8/9 aluminum intake plenum that I welded for a local shop. If you wanna come over and have a few brews I'd be happy to show you what I can.

#21

Registered User

iTrader: (2)

Join Date: Sep 2007

Location: Discovery Bay, CA

Posts: 1,569

Car Info: Evo X GSR, F250 Powerstroke Diesel

I literally took that pic today, I did that last night. Its my 3rd one so far and they keep getting better. Aluminum is a tricky and finicky biotch, it seems its never clean enough and I was used to welding steel and stainless and if your having contamination problems just turn up the gas and use a big cup....well the exact opposite is true for AL, I've turned my gas waaay down and Im using a much smaller cup to weld and the results are as shown. Its not really hard to weld AL, its just hard to make it look pretty and consistent unless you are welding on really clean metal.

#22

Registered User

iTrader: (2)

Join Date: Sep 2007

Location: Discovery Bay, CA

Posts: 1,569

Car Info: Evo X GSR, F250 Powerstroke Diesel

What kind of welding Bruce? Mig is easy, stick is only needed for 1/4 plus metal! Tig is the tuff one, takes long time to get good and have nice steady looking welds. I've been welding for over 5 years off and on. I can show you mig in know time. I do alot of Mig and dualsheild witch is a wirefed stick welder. I have done stick long time ago, problem is not many use stick unless you don't have duelsheild or innershield welder's! The shop I work for has alot of newer welder's unlike my last shop I worked at!

IMO, stick welding (SMAW) is the hardest process to be great at, there are tons of mediocre flat position stick welders but VERY few excellent stick welders. And stick is not so forgiving for welding out of position like TIG because of the voltage it uses (voltage not amps, allot of folks don't know the relationship to the two) compared to TIG and heat it puts into the metal. Not to mention that a E6010 does not weld the same way a E7018 welds so the learning curve is much greater, allot more electrodes to learn how to work.

#23

Friendly Neighborhood Ogre

Thread Starter

iTrader: (6)

Join Date: Mar 2000

Location: www.gunatics.com

Posts: 19,930

Car Info: GUNATICS.COM

Hey Bruce, I got a garage full of metal fab equiptment if you are really interested in learning. I got a nice 200 amp AC/DC TIG and stick, and all kinds of metal fab tools. I am a AWS and ASME section IX certified pipe welder, and do allot of side work as well. Here is a evo 8/9 aluminum intake plenum that I welded for a local shop. If you wanna come over and have a few brews I'd be happy to show you what I can.

So, you're in discover bay? That's about what, an hour from San Jose? It takes me about 45mins to get to Livermore, so prolly like 1.5 hours eh? It would be well worth it, I'm just trying to remember where Discovery Bay is... I'd pay you for whatever time and effort (and materials of course).

Maybe we can get a small class going where we have a few guys show up who all pay you a certain amount (I dunno how much, you make the call) and teach us all at once. Everyone benefits and you get some extra cash.

Who's interested in a group-buy learning how to weld class?

#24

Registered User

iTrader: (2)

Join Date: Sep 2007

Location: Discovery Bay, CA

Posts: 1,569

Car Info: Evo X GSR, F250 Powerstroke Diesel

WOW! That is some BEAUTIFUL work! Not to say that the other stuff that was posted was bad or anything, just that photo sticks out because the welds are so nice.

So, you're in discover bay? That's about what, an hour from San Jose? It takes me about 45mins to get to Livermore, so prolly like 1.5 hours eh? It would be well worth it, I'm just trying to remember where Discovery Bay is... I'd pay you for whatever time and effort (and materials of course).

Maybe we can get a small class going where we have a few guys show up who all pay you a certain amount (I dunno how much, you make the call) and teach us all at once. Everyone benefits and you get some extra cash.

Who's interested in a group-buy learning how to weld class?

So, you're in discover bay? That's about what, an hour from San Jose? It takes me about 45mins to get to Livermore, so prolly like 1.5 hours eh? It would be well worth it, I'm just trying to remember where Discovery Bay is... I'd pay you for whatever time and effort (and materials of course).

Maybe we can get a small class going where we have a few guys show up who all pay you a certain amount (I dunno how much, you make the call) and teach us all at once. Everyone benefits and you get some extra cash.

Who's interested in a group-buy learning how to weld class?

#26

VIP Member

iTrader: (7)

Join Date: Dec 2002

Location: Stockholm

Posts: 7,441

Car Info: 2018 Golf R Variant

I live right over Vasco, maybe 15 minutes from Livermore. Haha, that is funny idea me teaching a class, but I don't care Im always willing to help out my forum community. A 255 cf tank of argon costs me about $80 to fill and would last the whole day welding all day, and then some. I have pounds of er70 (mild steel filler) and a ton of 309SS filler as well. Whats the goal? Just get a basic understanding or be proficient?

For myself, the goal is to get to the point where I can practice welding at home and make that meaningful, so I guess learning the basics, how to clean/prep and tend to the welding unit, good habits, that sort of thing.

#28

VIP Member

iTrader: (3)

Sign up for a junior college course dude. Most of them have night courses. One day a week. Way more structured.

I have a few buddies that are great welders but when you're learning from someone like that you have to take in to account their material costs and electrical costs.

I have a few buddies that are great welders but when you're learning from someone like that you have to take in to account their material costs and electrical costs.

#30

General Pimpin'

iTrader: (7)

I really feel that TIG is VERY easy to learn, I always reccomend learning with no pedal just filler and torch, then you learn how to control the puddle with quenching with filler. Then work to the pedal.

IMO, stick welding (SMAW) is the hardest process to be great at, there are tons of mediocre flat position stick welders but VERY few excellent stick welders. And stick is not so forgiving for welding out of position like TIG because of the voltage it uses (voltage not amps, allot of folks don't know the relationship to the two) compared to TIG and heat it puts into the metal. Not to mention that a E6010 does not weld the same way a E7018 welds so the learning curve is much greater, allot more electrodes to learn how to work.

IMO, stick welding (SMAW) is the hardest process to be great at, there are tons of mediocre flat position stick welders but VERY few excellent stick welders. And stick is not so forgiving for welding out of position like TIG because of the voltage it uses (voltage not amps, allot of folks don't know the relationship to the two) compared to TIG and heat it puts into the metal. Not to mention that a E6010 does not weld the same way a E7018 welds so the learning curve is much greater, allot more electrodes to learn how to work.

I may have to take you up on that offer as well. I've got a couple buddies that weld and I'm trying to talk my buddy in to getting his extra welder back form the chick he lent it too so I can borrow it and just start sticking stuff together.

I know 3 solid welders but I'd love to sit down and practice with you man. Your stuff is insane.

I have some fabrication I'm planning on doing and I'd prefer to do some of it myself instead of making my buddy do it all (used to build drones).